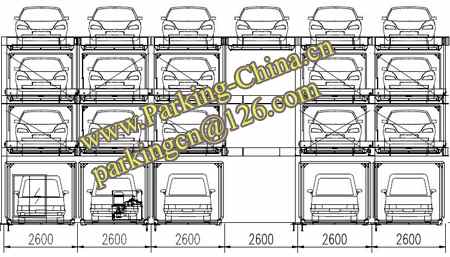

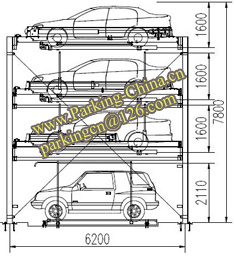

Model: PSH4

Back to

Products

Hydraulic Pallet Puzzle Parking System 4

Levels

Work Principle

This system is designed with 4 layers and multi-columns layout. Each layer is designed with a spare space as an exchanging space. All spaces can be auto-lifting freely except the spaces in the first layer and all the spaces can be auto-transverse moving except the spaces in the top layer. When a space needs to park or release a car, all spaces under the space will make a one space transverse moving to the empty space and forms a lifting channel under this space. In this case, the space will go up and down freely. When it reaches the ground, the car will go out and in freely.

Characteristics

-

Low area coverage and high usage rate of space.

-

The layers and columns will be added to raise the number of cars.

-

Made according to the customer's requirements.

-

It may be designed with full-closed style to adjust the surrounding environment.

-

It operates steadily without noise and with fast operating speed and short parking and releasing time.

-

Multi-channels safety protection and series of safety protection devices for anti-dropping, anti-crashing and anti-overloading.

Main Structure

-

Steel structure

-

Car Pallet

-

Lifting system

-

Sliding system

-

Hydraulic system

-

PLC control system

-

Safe-guard system

Technical Parameters

|

Item |

Parameters |

|---|---|

|

Mode of drive |

Hydraulic drive, Comb exchange |

|

Levels of system |

4 levels |

|

Mode of drive |

Hydraulic |

|

Size of car (L*W*H) |

5000mm*1850mm*1550mm |

|

Weight of car |

2000kg max /2500kg max |

|

Mode of operation |

Auto IC card/ Manual button |

|

Lifting motor power |

11KW |

|

Lifting speed |

12-20M/MIN |

|

Sliding motor power |

0.2KW |

|

Sliding speed |

8M/MIN |

|

Electricity |

AC 380V 50HZ, 3P5W; |

|

Safeguard devices |

Over-length, over-width, over height detection; car space with car or without car detection; wrong entrance detection Cylinder stroke protection, and anti-fall frame |

|

Warning devices |

Sound, light, electricity |

|

Malfunction indication |

Computer malfunction diagnosis, human-computer communication information display, liquid crystal display |

|

Parts appearance treatment |

Hot spray galvanized treatment and high-grade anti-corrosion painting |

|

Controller |

PLC, with control monitoring, IC card, manual and operative panel; |

|

Way of parking in and out |

Forwarding in and forwarding out; |